Service Hotline

+8613912995166

Brief description:PULVERIZER 80 Planetary ball mill consists of a grinding platform and a clump weight on the same sun wheel. When the machine is powered on, bowl revolves around the sun wheel axis and rotates itself at the same time, which is calle

Model:PULVERIZER 80

Model:PULVERIZER 80 Manufacturer:CHISHUN TECH

Manufacturer:CHISHUN TECH Update time:2021-12-06

Update time:2021-12-06 Visits:2625

Visits:2625TEL:+86 25-86795086 58000618

Skype:+86 139 1299 5166

Mobile:+86 139 1299 5166

E-mail:admin@nj-keyscience.com

//hojokin-news.com

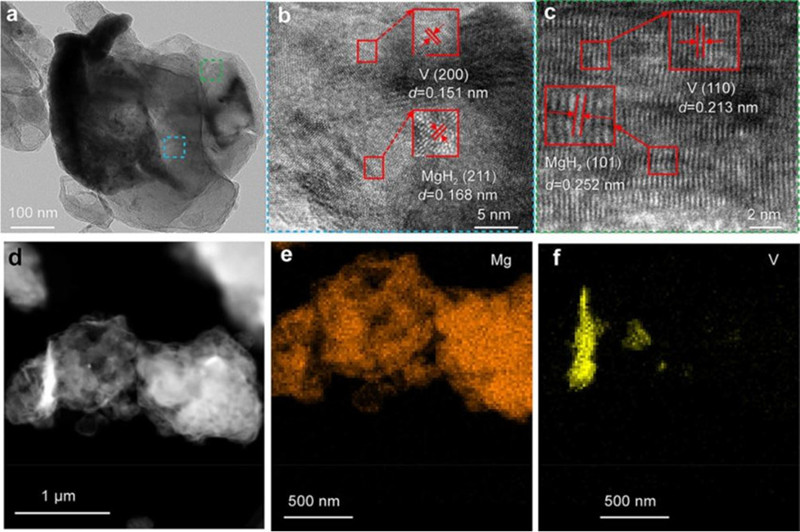

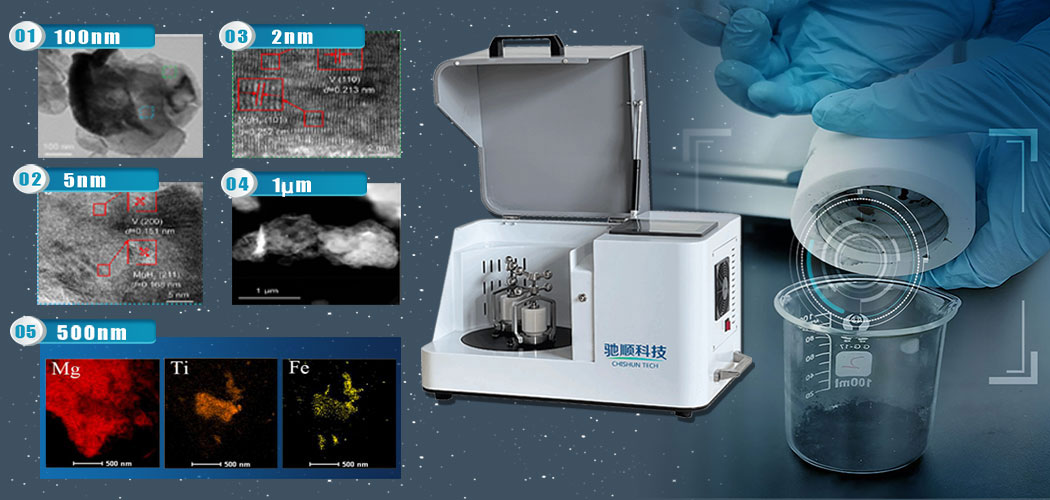

PULVERIZER 80 planetary ball mill utilizes the principle of planetary revolution and rotation, and the grinding ball moves at high speed in the grinding bowl. Through high-energy friction and impact force, the sample is crushed, which can quickly grind the sample to 1μ Below m. PULVERIZER 80 planetary ball mill is suitable for grinding hard to soft and brittle samples in the laboratory and samples in suspension. It is an ideal choice for ultrafine powder grinding, sample processing in the pharmaceutical industry, preparation of new materials, and mechanical alloying of materials.

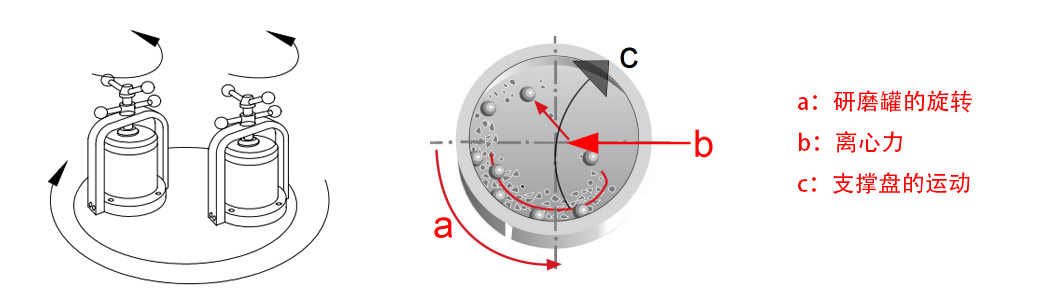

Working principle

The crushing and grinding of materials are mainly achieved through high-speed friction and collision between grinding balls. When the large disk rotates, the grinding tank containing sample materials and grinding balls rotates at high speed in the opposite direction around its center axis. At a certain speed, centrifugal force causes the sample and grinding ball at the bottom of the tank to separate from the inner wall of the grinding tank. The grinding ball travels at high speed inside the tank, further grinding the sample by hitting the tank wall. In addition, the impact collision between grinding balls also accelerates the consumption of sample size. The main disc of the solar wheel of the PULVERIZER 80 planetary ball mill has a rotational speed of up to 800rpm and a centrifugal force of up to 50g.

technical parameter

Maximum injection size: 5mm

Supporting grinding tank specifications: 25ml, 45ml, 80ml, which can handle two small amounts of samples

Discharge fineness:<0.1um (typical grinding time required to grind to analytical grade fineness is not more than 5min to ensure work efficiency)

Inert gas grinding: acceptable (only in glove box)

Grinding method: dry method, wet method

Typical grinding time: 5 minutes

Main disc speed: 100-800rpm, continuously adjustable, grinding tank speed can reach 1600rpm

Transmission ratio (planetary disc: grinding bowl): relative transmission ratio=1:2

Effective diameter of main disc: 290mm

Grinding tank safety device: dual safety lock, rotary locking device

Centrifugal acceleration (g=9.81m/s2): 50g

Cooling grinding: Supported, requires optional cooling device

Electrical certification: UL certification, CE certification

Safety certification: Passed EU CE certification (S/N: 802693615232)

Electrical description: AC220V 50-60Hz 0.75kw

Control method: Programmable touch LCD screen, supporting intermittent operation, timed operation, alternating operation, data storage, and abnormal alarm

Exhaust device: Double fan forced ventilation design, effectively reducing the temperature of the grinding chamber during ball milling process

Grinding tank material: stainless steel, modulated steel, vacuum stainless steel, tungsten carbide, zirconia, silicon nitride, agate, alumina

Grinding medium specifications: 1mm, 3mm, 5mm, 6mm, 8mm, 10mm, 15mm

Equipment weight: net weight 55kg

Outline dimensions: 64*40*40cm

Main features

1. The planetary high-energy ball mill is mainly used in laboratory laser spectral analysis, precision grinding of chemical, pharmaceutical, biological, glass, ceramics, building materials, coal raw materials, pretreatment of laboratory samples in the food industry and material technology, geology, mineralogy and nuclear industry research fields.

2. The grinding time, cooling time, and grinding frequency can be set to the nearest second.

3. Analyzing pure grade grinding materials ensures pollution-free grinding.

4. The instrument is easy to clean and minimizes sample contamination.

5. Inert gas can be filled for grinding.

6. Can process 2 samples simultaneously.

7. Can achieve final particle size<0.1 μ Superfine powder grinding of m.

8. Multiple devices of different materials are available for selection, including stainless steel, modulated steel, vacuum stainless steel, tungsten carbide, zirconia, silicon nitride, agate, and alumina.

Wechat consulting

Copyright © Nanjing Chi Shun Technology Development Co.,Ltd. Tel:86-25-86795086 58000618 58000718 E-mail: admin@nj-keyscience.com